Know how -

many years of experience and comprehensive know-how in plastic injection molding make the difference - benefit from it!

At TECHNOPLAST, the term "know-how" is backed by many years of experience in a wide range of areas of the plastics industry. We see ourselves as your imaginative, experienced problem-solving partner in the search for reliable, competitive and cost-effective production solutions with quality standards. In doing so, we also like to take unconventional new paths.

Many individual solutions are the result of intensive discussions with customers, our experts and the practitioners at the machines.

That's why our solutions work.

We process almost all common plastics:

PS

SAN

ABS

ASA

PMMA

POM

PVC

PBT/PC

PPO V0

PA 6.6. CF

PC

PC-ABS

PA 6

PA 66 GF

PBT

PEEK

LLDPE

PPTV

PA 6 GF

LPC

PE

PP

PU

TPE

TPV

ABS/PA

PP GF

PA 6 GB

Our injection molding equipment:

Injection molding machines:

From 35t to 650t clamping force

Part weights:

from 1g to 3,700g

Strengths in injection molding:

very demanding visible parts, 2K technology,

gas injection molding

Lot sizes:

from 1,000 to 2million pieces

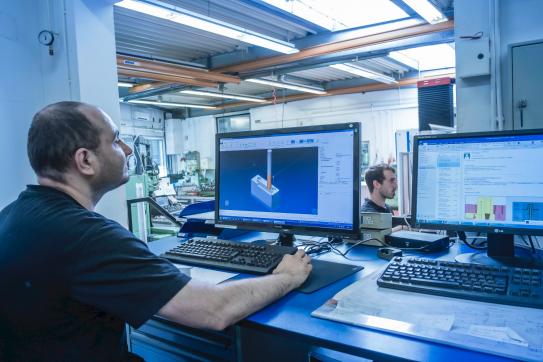

Planning, CAD, Technology

Idea - Planning - Technology - Consulting

Often the right implementation idea decides on the economic success of a customer project. That's why we give equal weight to theory and practice when designing a project.

We are your professional partner in planning, CAD and technology.

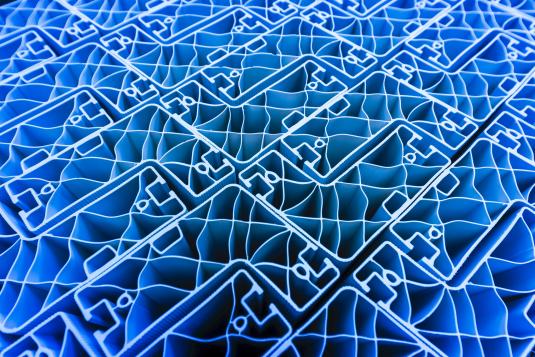

Own mold and tool making

Under the slogan "We bring injection molding into shape" we are available as a creative partner:

Conception and consulting

Tool design

CAD conversions

Mold and tool making

Standards for the modern plastics industry

We have the necessary resources and tools for the machining and repair of our often very complex injection molds weighing up to 6 tons.

Our in-house tool and die shop covers our direct production needs. Under our management, high-performance, highly specialized external partners take on special tasks and complex elaborations. As a well-coordinated team, we thus master all technical hurdles!

Custom injection molding

Plastic quality production at the highest level at toughly calculated costs. Our customers appreciate us as a partner in production and technology because we are used to thinking outside the box and thinking ahead economically. This guarantees our customers' market advantage and secures our prospects - even for the day after tomorrow.

Reliability, flexibility, creativity, cost-effectiveness, state-of-the-art machine technology - these are the pillars on which TECHNOPLAST's partnership-based production concept rests.

Value-added product refinement

Our strength also lies in the economic overall solution of complex tasks. From injection-molded individual components, to versatile finishing operations, individual or component assembly work, to system group creation and testing, we are happy to carry out all conceivable measures for you, also as a package solution.

- Drilling, turning and milling work

- Special cleaning, testing work

- Assembly and assembling work

- Screen and pad printing,

- confection and packaging

- and much more.

Assembly of components

- Adhesive assemblies

- Single and subassembly assembling

- Screen and pad printing

- Routine testing

- Confection & Packing

- and much more ...

Logistic Services

We get your products moving:

Via Just-In-Time delivery and our logistics service, we ensure limitless availability - around the clock and around the globe. Our assembly and call-off warehouse enables flexible delivery readiness with economical batch sizes.

TECHNOPLAST - your intelligent service partner with

added value.

References

We would be happy to name our informative references. We work for well-known companies throughout Europe. We are sure you will understand that we would like to present you product references and sample solutions only in direct contact. Please contact us for this purpose:

Info and service phone:

+49-(0) 7192 / 935 98-0

Fax: +49-(0) 7192 / 900-286

E-Mail: info@technoplast.net

Thank you for your interest!